Wire-to-board connectors are an essential component of many electronic devices. They allow for the transmission of signals and power between a circuit board and an external wire. These connectors are commonly used in various industries, such as automotive, aerospace, medical, and consumer electronics. In this article, we will explore the applications of wire-to-board connectors, their advantages, types, how to select the right connector, installation, and maintenance.

What are Wire-to-Board Connectors?

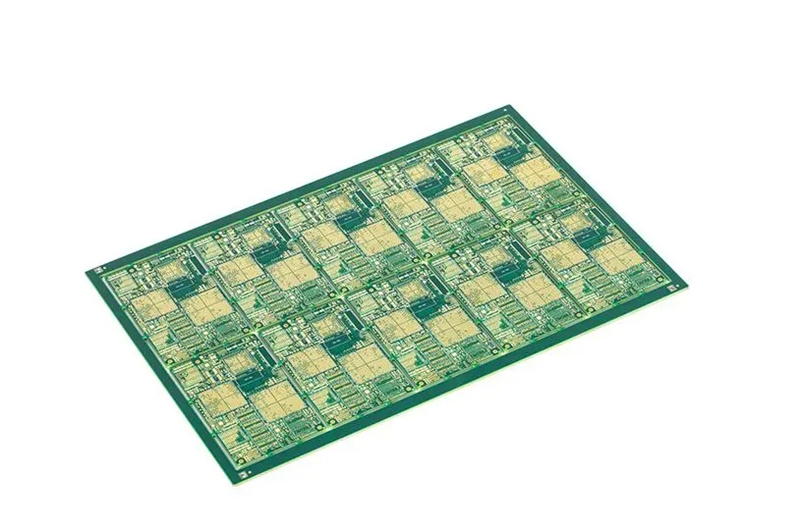

Wire-to-board connectors, also known as PCB connectors, are electrical connectors that connect wires to a printed circuit board (PCB). The basic design of a wire-to-board connector consists of two parts, the housing and the terminal. The housing holds the terminal, and the terminal is responsible for making the electrical connection between the wire and the PCB.

Wire-to-board connectors are available in different sizes and configurations, and their specific use is determined by the number of pins or contacts required, the current and voltage ratings, and the type of wire they are compatible with. Some wire-to-board connectors are designed for a specific industry, such as the automotive industry, and are designed to withstand harsh environments, high temperatures, and vibrations.

Applications of Wire-to-Board Connectors

Wire-to-board connectors are used in various industries, including:

Automotive Industry

Wire-to-board connectors are commonly used in the automotive industry to connect various components, such as sensors, actuators, and switches, to the electronic control unit (ECU). The connectors used in the automotive industry must be durable, reliable, and able to withstand high temperatures, humidity, and vibrations. They must also be resistant to chemicals, oils, and other harsh substances that may be present in the engine compartment.

Aerospace Industry

The aerospace industry also relies heavily on wire-to-board connectors to connect different components of an aircraft, such as sensors, avionics systems, and lighting systems, to the main control system. Connectors used in the aerospace industry must be lightweight, compact, and able to withstand extreme temperatures, vibrations, and pressure changes.

Medical Industry

Wire-to-board connectors are also used in the medical industry for a variety of applications, such as in medical devices, diagnostic equipment, and laboratory equipment. The connectors used in the medical industry must be durable, reliable, and able to withstand sterilization processes.

Consumer Electronics

Wire-to-board connectors are commonly used in consumer electronics, such as mobile phones, computers, and gaming consoles. These connectors are designed to be small, lightweight, and able to handle high data transfer rates.

Advantages of Wire-to-Board Connectors

Wire-to-board connectors offer several advantages over other types of connectors, such as:

- Space-saving design: Wire-to-board connectors are designed to take up minimal space, making them ideal for use in small electronic devices.

- Easy to install: Wire-to-board connectors are easy to install and remove, making them ideal for applications where frequent maintenance is required.

- Increased reliability: Wire-to-board connectors provide a secure, stable connection, reducing the risk of electrical failures and short circuits.

- Increased efficiency: Wire-to-board connectors can help reduce the amount of time and effort required for assembly, resulting in increased efficiency and cost savings.

Types of Wire-to-Board Connectors

Wire-to-board connectors are available in different types, configurations, and sizes, and each type is designed to meet specific requirements. Some common types of wire-to-board connectors include:

Pin Header Connectors

Pin header connectors consist of a row of pins that plug into a PCB. They are commonly used in applications where a secure connection is required and the connector is not intended to be removed frequently.

Shrouded Header Connectors

Shrouded header connectors are similar to pin header connectors, but they have an additional housing that covers the pins, providing extra protection and preventing accidental disconnections.

Box Header Connectors

Box header connectors consist of a box-shaped housing that contains the pins. They are commonly used in applications where a higher number of pins are required, and the connector is not intended to be removed frequently.

Crimp Connectors

Crimp connectors are used to terminate a wire by crimping the connector onto the wire. They are commonly used in applications where a reliable and secure connection is required, such as in the automotive industry.

IDC Connectors

IDC (Insulation Displacement Connector) connectors are designed to make a connection with a wire without the need for stripping or soldering. They are commonly used in applications where a fast, reliable, and secure connection is required, such as in the telecommunications industry.

SMT Connectors

SMT (Surface Mount Technology) connectors are designed to be mounted directly onto a PCB. They are commonly used in applications where space is limited, and the connector needs to be mounted flush with the surface of the PCB.

How to Select the Right Wire-to-Board Connector

Selecting the right wire-to-board connector requires careful consideration of several factors, including:

- The number of pins required

- The current and voltage ratings

- The type of wire the connector is compatible with

- The environmental conditions the connector will be exposed to

It is essential to choose a connector that is compatible with the specific requirements of the application. Choosing the wrong connector can result in electrical failures, short circuits, and other problems.

Installation and Maintenance

Proper installation and maintenance of wire-to-board connectors are essential to ensure optimal performance. Before installing a connector, it is essential to ensure that the wire is properly stripped and crimped. The connector should also be inserted into the PCB correctly and securely.

Regular maintenance, such as cleaning and inspecting the connector for damage, can help prevent issues from arising. If a connector is damaged or shows signs of wear, it should be replaced immediately.

Conclusion

Wire-to-board connectors are an essential component of many electronic devices, and their applications are vast and varied. By understanding the different types of wire-to-board connectors, their advantages, how to select the right connector, and proper installation and maintenance procedures, it is possible to ensure optimal performance and reliability. When choosing a wire-to-board connector, it is essential to consider the specific requirements of the application and choose a connector that is compatible with those requirements. With the right connector and proper installation and maintenance procedures, wire-to-board connectors can provide a reliable, efficient, and space-saving solution for connecting wires to a PCB.